Materials Traceability Leader Circulor Expands Hyperledger Fabric-Based Solution to Underpin Digital Battery Passports

Summary:

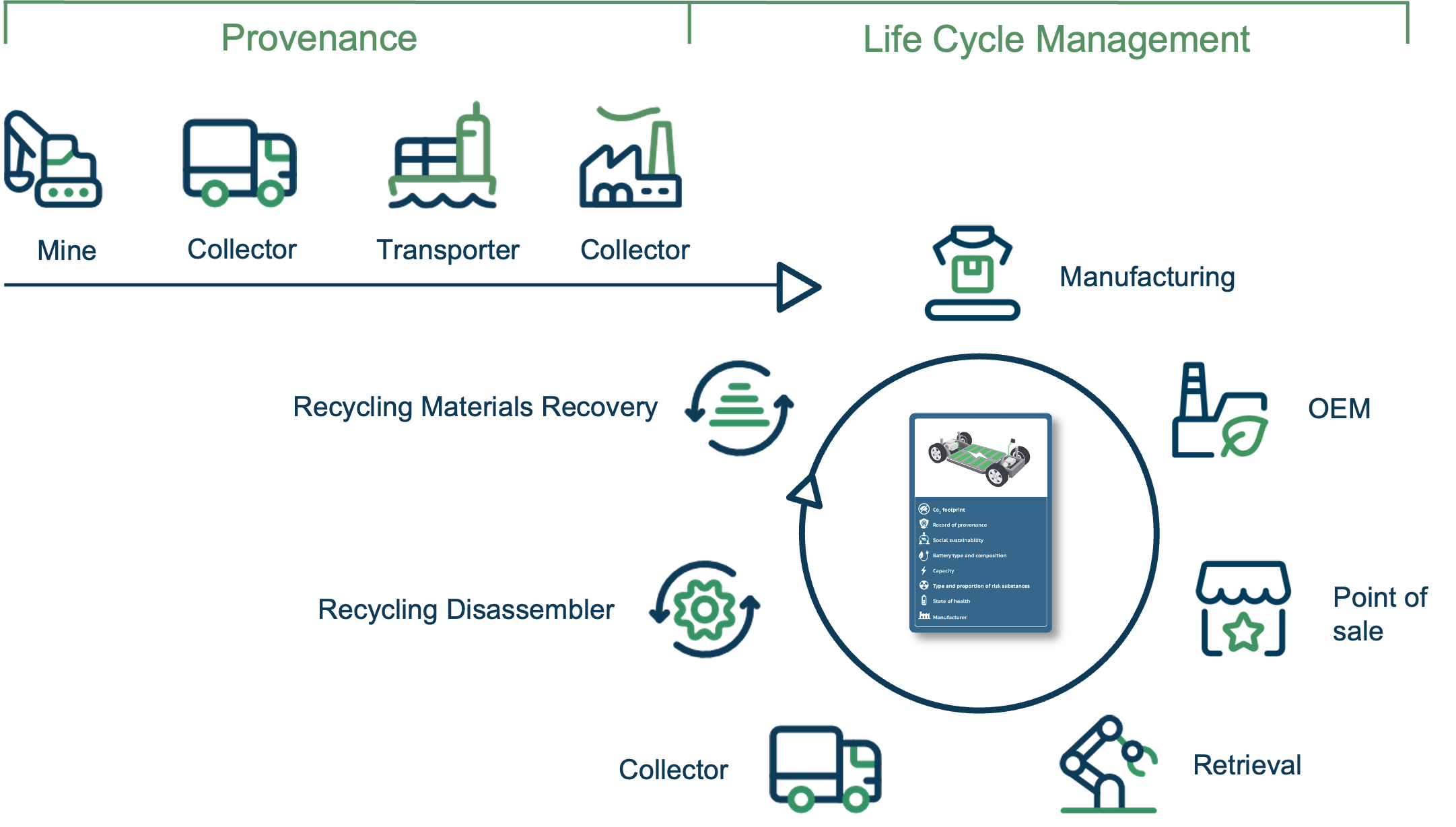

- Circulor’s Battery Passport solution tracks raw materials through supply chains from extraction to the end of life.

- Circulor, the global leader in supply chain traceability, expanded its initial focus on the cobalt supply chain into tracking multiple raw materials at every step in the manufacturing and recycling value chain.

- As Europe’s sustainability regulations come into effect, Circulor’s Battery Passport solutions helps ensure battery manufacturers and their supply chains comply, while offering extended business value.

- Hyperledger Fabric ensures data integrity at each point in the process while guaranteeing various stakeholders can only see relevant information.

Goals

-

Enable traceability and compliance processes for companies that must meet global regulations, such as the EU Battery Regulation.

-

Guarantee data integrity from mining raw critical minerals to the end of battery life.

-

Expand the scope of passport information to improve disposal or recycling processes as batteries end their lifecycles.

-

Increase the value-add for manufacturers using technology to improve transparency across supply chains.

Approach

- Assess the business challenge

- Create Circulor’s Battery Passport solution with Hyperledger Fabric

- Provide benefits across the value chain

- Roll out the solution at scale

- Expand the benefits of Digital Product Passports beyond compliance and batteries

Results

- Since 2017, Circulor has enabled manufacturers to track critical minerals and carbon emissions across 30 global supply chains including over 125 facilities

- Digital Battery Passports are more than just compliance

- Customers have traced materials for over 150 million batteries and 500,000 electric vehicles on the road today.

- Customers have recorded over 2 billion traceability data points, equivalent to 250 million uniquely identifiable products.

Summary

As the demand for batteries grows worldwide, so does the demand for base and rare earth metals. The global demand for lithium, for example, is expected to increase 89-fold by 2050 and there’s growing concerns on how to ensure sustainable and ethical sourcing.

Traceability is the process of following a physical material—from mine to final product— in order to prove its provenance and production journey, as well as associated ESG characteristics and embedded carbon across Scope 1, 2, and 3 emissions. To be confident in the provenance of the end product, you need to be confident in the data that has been input at every stage of the supply chain

This is where Circulor comes in. The company works with companies operating across the battery value chain, including OEMs (such as Volvo Cars, Polestar, Volkswagen, Daimler and BMW), midstream producers, miners, and recyclers.

Circulor gives manufacturers and material providers a cost-effective, and secure way to ensure that all batteries entering the European market adhere to sustainability and responsibility guidelines required by the recently passed EU Battery Regulation.

In addition to its core traceability solution, Circulor has developed a battery passport that collates, stores, and displays relevant information about a battery’s entire life cycle. By tracking activity from mine to manufacturer, as well as in life, second life, and recycling, it improves supply chain visibility, reduces risk, and streamlines pathways to second life and recycling—all while complying with regulations in a simple way.

Assessing the Business Challenge

As of 2027, the European Union will mandate that companies introducing batteries into the European market include a digital battery passport for each battery that proves sustainable, responsible, and circular sourcing. The new regulation concerns all electric vehicle (EV) batteries, light means of transport (LMT) batteries, and industrial batteries with a capacity over 2kWh. Other countries and economic regions are already following suit.

However, bringing ethically and sustainably sourced batteries to the consumer marketplace isn’t simple. Manufacturers face a host of challenges along the supply chain.

Many mines may not use technologies that enable streamlined tracing. Paper records are easily altered and tough to authenticate, so verification of information is a lengthier process with more room for error or fraud. In addition, some suppliers may be hesitant to publicly share all the information out of concern for revealing too much about practices to their competition. Therefore, it’s key that this is done digitally and securely through industrial IoT applications – leaving no room for human error or manipulation.

Without detailed digitization and robust security, someone could easily alter material records. It’s also possible for the materials themselves to be altered, potentially compromising quality or quantity and introducing risk for manufacturers.

“It’s really balancing transparency, bringing data from along the supply chain and continuing through the product life, with confidentiality,” says Nikki Kitson, Product Manager at Circulor. “As some stakeholders shouldn’t see some of that data.”

“It’s really balancing transparency… with confidentiality.”

Creating Circulor’s Battery Passport solution with Hyperledger Fabric

Circulor had already implemented a solution at scale to track ethically sourced minerals—which is essential to underpinning the data requirements of battery passports.

In 2018, Circulor provided the first-ever mine-to-manufacturer traceability of a conflict mineral to prove that tantalum ore from three mines in Rwanda was mined, transported, and processed under OECD-approved conditions, without child or enslaved labor.

At each supplier along the chain, digital information is gathered and tracked and then attached to the minerals, rare earths, or other materials or processes. The “digital twin” tracks each material from origin through the battery's life, allowing visibility into the physical flow of critical materials from extraction to final production. The platform works with any form of tag containing a unique identifier to tag materials at source. The lowest cost option is to use QR codes, which are self-generated by registered users.

Customers can also see ESG characteristics and embedded carbon across Scope 1, 2, and 3 emissions, allowing more informed decision-making.

The Circulor app provide strong anti-fraud protocol and capabilities before posting data to the blockchain, where smart contracts validate the records collected from suppliers and post them to the shared ledger. For example, using GPS tracking and facial recognition, the protocol verifies that the process took place at an accredited facility, at the expected time, for the expected duration, in a way that matched the site’s declared capacity.

The company uses Hyperledger Fabric as the platform for its distributed ledger and smart contracts. The Hyperledger Fabric-based framework supports high-performance levels and offers data confidentiality features required to support multiple customers across an integrated blockchain network.

The Circulor solution also incorporates Oracle Cloud Infrastructure (OCI) blockchain. It provides built-in integrations from the blockchain to a best-in-market platform and infrastructure services, including analytics and databases.

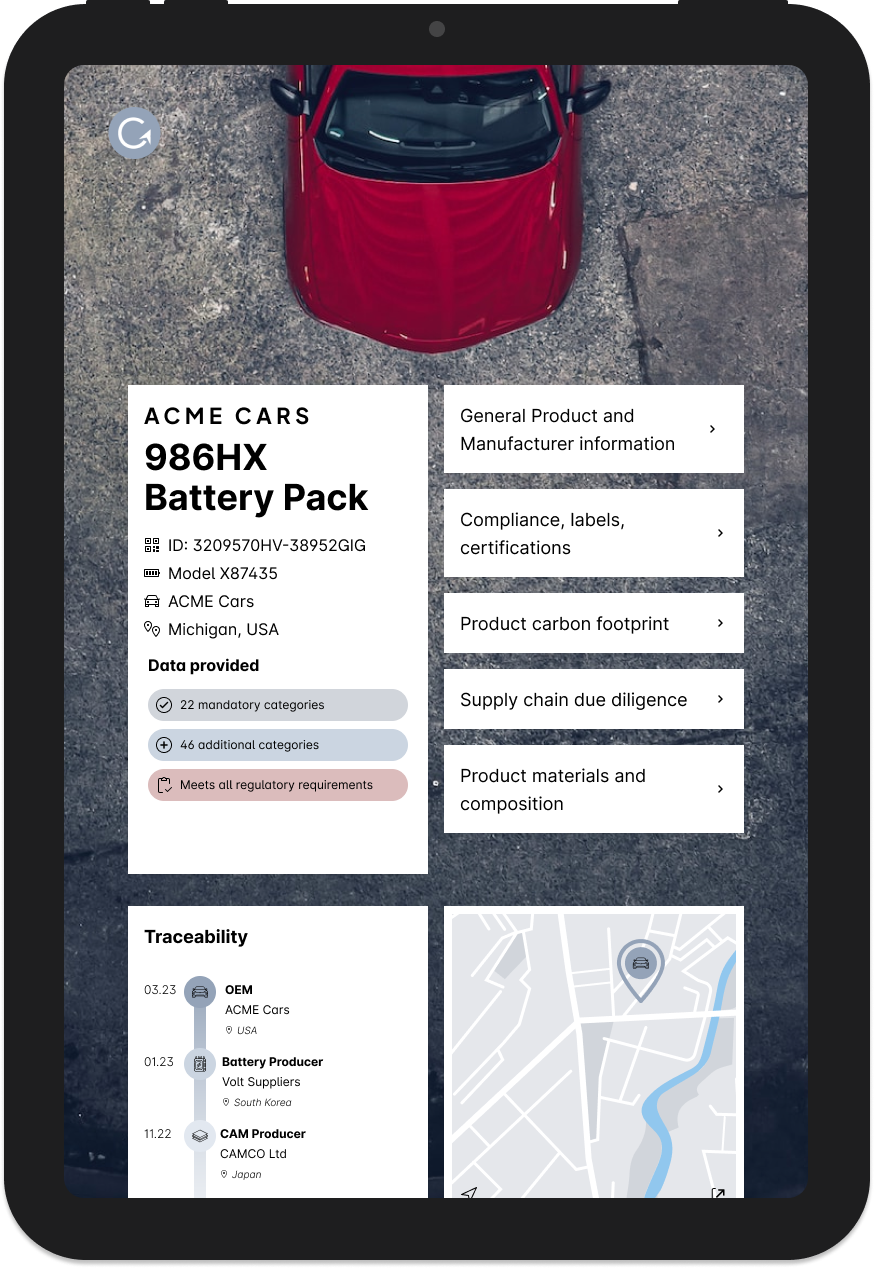

This granular supply chain information for materials and products is essential in underpinning new requirements for digital battery passports. Circulor’s Battery Passport enables customers to comply with the regulation, demonstrating requirements like embedded carbon footprint, responsible sourcing, recycled content, and state-of-health performance.

“With Circulor’s Battery Passport the manufacturer is not just claiming the provenance of the materials, or the amount of recycled content in their battery. The materials have been tracked and traced from origin, so there’s granular evidence underpinning the claims.”

Providing Benefits Across the Value Chain

The battery passport goes beyond manufacturing and tracks batteries through lifecycles across the value chain—all the way to second life and eventually recycling.

“What’s great about the battery passport is that we are now extending the traceability journey beyond the factory gate, to include the full product lifecycle,” says Nikki Kitson, Product Manager at Circulor. “Our Battery Passport will record in-use information about battery health, product repairs, and eventual second life or recycling information.

“All of this is carried on a QR code,” she says. “Depending on your role in the value chain, you have different rights to access different data.”

For example, a recycler might find information about how to dismantle the battery or the product's composition but won’t see information irrelevant to the recycling process.

The key to Circulor’s Battery Passport is proof—the evidence underpinning the data about each battery. “With Circulor’s Battery Passport the manufacturer is not just claiming the provenance of the materials, or the amount of recycled content in their battery. The materials have been tracked and traced from origin, so there’s granular evidence underpinning the claims,” says Kitson.

“Manufacturers get more than regulatory compliance,” says Coenraad van Deventer, Chief Technology Officer at Circulor.

For example, if you contract with a supplier to receive recycled materials, you may never know for sure that’s what you received. This is especially true if the contract is several years old. “Second and third level suppliers may have changed,” explains Deventer.

“Our traceability is active traceability, it’s continuous,” he says. “You have proof—in real time—that you are getting what you paid for, rather than relying on occasional audits or assessments.”

“You have proof—in real time—that you are getting what you paid for”

“Traceability can help organizations with supply chain risk management, understanding carbon emissions, and improving customer relations,” says Kitson. For example, she cites the potential of issuing highly targeted recalls if a certain batch of batteries experience failure or defect. “You can recall a smaller segment of those batteries.”

In addition, manufacturers will have access to data about how their products are used and how long they last in certain conditions or geographies. “They might discover information about a material’s durability or performance, informing sustainable manufacturing,” says Kitson. “There’s a lot of value in the data underpinning the battery passport, beyond just meeting regulation.”

Deventer agrees, and not just for manufacturers but the industry as a whole. “This traceability of the supply chain increases transparency. The whole ecosystem gets a bigger view than any individual company could get,” he says.

Rolling Out the Solution at Scale

Circulor works with each manufacturer to onboard each supplier along its supply chain and explain what data to collect. “As a neutral third party, we can talk to suppliers about data they might not be willing to share for competitive reasons, such as total output volume,” says Kitson.

In addition, Circulor uses REST APIs and integration adapters that allow the solution to connect directly with existing systems and applications.

Since its launch in 2018, Circulor’s materials traceability solution has enabled manufacturers to track critical minerals and carbon emissions across 30 global supply chains.

Circulor’s customers have recorded over 2 billion data points for the equivalent of 250 million uniquely identifiable products and constituent materials for over 150 million batteries and 500,000 EVs. And they continue actively contributing traceability and sustainability data.

As the most mature battery traceability platform on the market, Circulor has the largest network of battery suppliers and value chain participants on its platform. And because many manufacturers use the same suppliers, onboarding and adoption become more and more streamlined as the Circulor platform grows further.

“The extensive network on our platform makes implementation for new customers especially efficient and straightforward. Once we’ve onboarded the customer and they start to share data onto our platform, adding a supplier or material is quite easy,” says van Deventer. “Each one sends us the new material type of data. Some business rules might change, but 90% of the onboarding has already happened.”

“The extensive network on our platform makes implementation for new customers especially efficient and straightforward. Once we’ve onboarded the customer…adding a supplier or material is quite easy”

Expanding on the Benefits of Digital Passports Beyond Compliance

Digital product passports are still expanding, and various stakeholders are having ongoing conversations about tracking and tracing other goods, such as consumer electronics and solar panels.

Besides regulatory compliance, digital product passports have other value-added benefits, including supply chain risk management, understanding carbon emissions for targeted decarbonization strategies, and improving customer relations.

Circulor plans to work with customers and policy makers globally to evolve its Battery Passport and combine with emerging technologies to drive the sustainability and circularity of batteries.

“At the moment, the focus is on batteries as the first good to be accompanied by a digital passport,” says Kitson. She envisions a future where every component inside a product has its own digital passport that accompanies the component throughout its lifecycle.

“We’re working towards a world where we’ve got a chain of custody of different digital product passports, underpinned by immutable traceability,” she says.

Image: Front-end app example

About Circulor

Circulor is the leading sustainable supply chain traceability provider. Headquartered in the UK, with a global footprint across Germany, the US, Singapore, and Australia, Circulor enables businesses to fully analyze, track, and manage their supply chains to ensure responsible sourcing and improve sustainability. Circulor does this by providing an enterprise software platform, which creates a reliable chain of custody of materials and attaches GHG emissions and other ESG data directly to the flow of materials. To learn more, visit https://www.circulor.com/

About Hyperledger

Hyperledger is an open source effort created to advance cross-industry blockchain technologies. It is a global collaboration including leaders in banking, finance, Internet of Things, manufacturing, supply chains, and technology. The Linux Foundation, the nonprofit organization enabling mass innovation through open source, hosts Hyperledger. The Linux Foundation also enables a worldwide developer community to work together and share ideas, infrastructure, and code. To learn more, visit https://www.hyperledger.org/